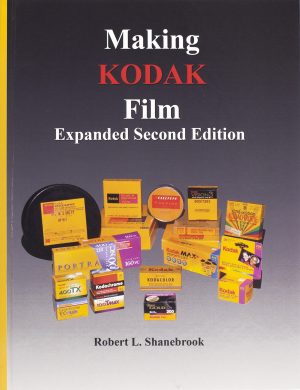

Making Kodak Film

Expanded 2nd Edition by Robert L. Shanebrook

The first edition was published in 2010. In 94-pages, it gives a high level view of film manufacturing technology. It is suitable for those with a general interest in photography and is easily understood by high school students. It explains how film is made in a state-of-the-art factory. The second edition gives far more information in its 470-pages.

In addition to the information in the 1st edition the 2nd edition adds:

- History of film base manufacturing including American Film, cellulose nitrate, cellulose acetate, Estar Base and others.

- Expanded discussion of historic and modern emulsion making processes and equipment.

- History of coating technology and expanded discussion of curtain coating including photographs of an operating Kodak curtain coater and the thread-up path of Kodak’s Building 38 Film Coating Machine.

- Expanded description and photographs of finished film configurations and the finishing processes. Of special interest is motion picture film finishing using high speed T-perforators.

- Detailed descriptions of photographic film image forming mechanisms for black-and-white films, color negative films, Ektachrome Films, and Kodachrome Films.

- Technical descriptions and history of Kodak Films that are used for consumer, professional, motion picture, x-ray, micrographic, graphic, aerial, and scientific applications.

- Description of past and current Kodak Worldwide manufacturing plants, interactions between the plants, and technology transfers.

- First-hand description of working in Kodak’s film business in the 1980’s.

- Information based on private communications with over 100 photographic experts.

- Addition of over 225 photographs and diagrams.

- Identification of sources of information; over 600 footnoted references.

- A table of figures and an index to facilitate finding information in the book.

The book is 470 pages, 8.5 x 11 inches and four-color printed on 80-pound glossy paper. It is gloss-film lamination hard-cover bound. Shipping weight is 5 pounds. It was printed and bound in Rochester, NY USA.

There are 402 figures. It contains over six times more words than the 1st edition. It is printed on a HP Indigo Digital Press. The color quality is excellent. To assure book quality, the author personally inspects every book. Books have been destroyed that were not the best quality.

Who would enjoy reading Making KODAK Film?

Current and former Kodak Employees

“Making KODAK Film” is of great interest to Kodak employees and retirees. Now for the first time an overview of the film manufacturing process is explained in simple language. This allows Kodakers to gain a greater understanding of how their efforts contributed to the quality of Kodak films. It also provides an opportunity to explain their role at Kodak to family members and friends.

Photographic conservators and archivists

For those with the important responsibility of preserving motion pictures and photographs, “Making KODAK Film” provides a unique explanation of how the films are made. Determining and implementing the protocols needed to preserve these critical materials is facilitated by thoroughly understanding how the materials are created.

Cinematographers and very serious film photographers

Cinematographers and photographers understand how their skills improve the quality of their photographs. The book provides photographers with an understanding of the operations required to provide films that they need and gives them a better understanding of film, the tool that is essential in making film images.

About Bob Shanebrook

Bob Shanebrook graduated from Rochester Institute of Technology and worked at Eastman Kodak Company for 35 years before retiring in 2003. At Kodak he worked as an industrial photographer, researcher, product development engineer, manufacturing manager, company spokesman for Professional Films, and for more than twenty years was a Worldwide Product-Line Manager for Kodak Professional Films.

In 1969 he worked on the Apollo Lunar Surface Close-Up Camera that was flown on Apollo 11 to 15. He also briefly worked supporting NRO's Reconnaissance Satellites Gambit-3 and Manned Orbiting Laboratory.

He was then offered a position in KAD Research Laboratory where he worked on image evaluation, liquid crystals for imaging, and other electronic imaging devices. In the Photographic Technology Division he worked on new thermal films, microfilms, x-ray films, and then experimental T-Max Films.

Beginning in 1981, he became engaged in nearly all aspects of Kodak's black-and-white and professional film business. As Worldwide Product-Line Manager he was heavily involved in designing, manufacturing, and commercializing photographic products including:

- Polyfiber Paper

- Polyprint RC Paper

- Polycontrast III RC Paper

- Elite Fine-Art Paper

- EKTAMAX Paper

- T-Max 100, T-Max 400, and T-Max p3200 Films and T-Max Developer, T-Max RS Developer

- Duraflo Developer

- Technical Pan Film 120 and sheets Technidol Developers

- Ektachrome Films: 100, 100 Plus, 64, 200, 64T, DUP film

- Process E-6 chemicals and Q-Lab Process Monitoring Service

- Kodachrome 200 and Kodachrome 64 in 120-size

- Process K-14 chemicals and Kodachrome Professional Film Processing Laboratories

- Ektapress Films: PJA, PJB, PJC, PJM

- Professional Internegative Film

- Kodak Pro 100, 100T, 400, and 400MC Films

- Ektacolor Pro-Gold 160 and Gold 400 Films

- Miyabi Film, Japan

- Profoto, Pro Image, Image 100, Ultima Films

- Portra Films: 160NC, 160VC, 400NC, 400VC, 800, 100T, 400BW

- Endura Metallic Paper

- 2002 Reformulation of:

- T-Max 100, Tri-X 400, Tri-X 320 and 400, High speed Infrared, Plus-X Films

His technical photographic papers have been published by Association for Information and Image Management, Radiological Society of North America, and Society for Imaging Science and Technology.

He was instructed by and later worked on photographic projects with John Sexton and Ansel Adams.

At Kodak he won the Everest Award for Product Excellence and the Outstanding Innovation Award for film technology advancements.

He was on the Board of Directors of the Friends of Photography, Carmel and San Francisco, California.

Bob consults in the fields of silver halide technology and photographic history at George Eastman Museum, Rochester, NY. and commercial clients.

On behalf of the American National Standards Institute (ANSI) he is a voting delegate to International Standards Organization: Photography Technical Committee.

He and his wife Lynne live and sail on Irondequoit Bay, near Rochester, NY. They have adult children, Stefanie and Adam and four grandchildren.

He can be contacted at: makingKODAKfilm@yahoo.com

© 2020 Robert Shanebrook

KODAK.com 2019:

There are two types of “filmmakers” - those who translate their visions onto film and those who design and manufacture the physical product. Robert L. Shanebrook, one of the world’s foremost experts in making film products, delves into the world of film technology. His book provides an accurate, in-depth view of how film is made in a state-of-the-art factory. Anyone interested in photography and those wanting an education on the making of film will find his research fascinating.

Bob Shanebrook managed many of the professional photographic film products during his 35-year career at Kodak, including both research and manufacturing. In a real way, this is the creator telling the story of creation as pertains to the making of film.